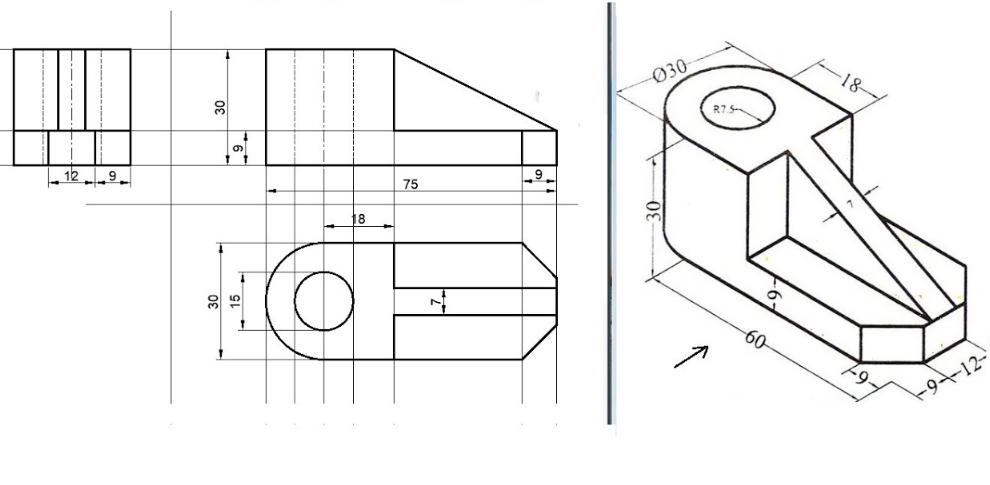

The front sight is frequently the most identifiable facet of a technical drawing. The primary objective of the front sight is to deliver a clear, simple depiction of the object that highlights essential features, measurements, and percentages.

Building upon this, the leading sight complements the façade by giving information concerning the deepness of the object. This sight allows designers to see just how broad and deep the things is, eliminating obscurity that may occur from the first front view alone. The leading view aids to visualize connections in between different components of the design, making it simpler to recognize the layout of elements, specifically in intricate systems with numerous overlapping components. When used properly, the top view can aid communicate vital facets of functionality and spatial plan that are essential for manufacturing and assembly.

The side sight, also referred to as the profile sight, supplies yet another point of view by showing the things's height and depth. It is particularly helpful for showcasing functions that may not be as noticable in the front or leading views. By including the profile right into the technical drawing, developers ensure that all dimensions can be precisely provided, producing a thorough sight of the things. In addition, the profile can highlight contours, slopes, or any protrusions that may be considerable to the style's operational effectiveness and aesthetic charm.

Explore technical drawing views the important role of technical drawing in design and design, highlighting crucial views such as front, top, side, section, and isometric point of views that guarantee accurate communication and execution in design and production.

Area views are one more crucial element of technical drawings. They provide a way to show the inner attributes of a style that may not be obvious from the external views. A section sight is developed by slicing through the object and revealing its inner geometry. This method enables engineers and architects to check out complex features such as dental caries, forms, and products within a design. Including area views assists to avoid confusion in recognizing the layout, particularly for elaborate assemblies where inner setups may impact capability or manufacturability. By developing these cuts in the item, technical drawings come to be a lot more helpful, permitting more detailed evaluations of exactly how components will certainly communicate once constructed.

This sight provides a three-dimensional depiction of the object, supplying a practical illusion of deepness and scale without calling for complicated perspective estimations. Isometric views can be unbelievably useful in sharing the general format of an item, specifically to individuals that may not be fluent in reading technical illustrations.

In addition to these essential views, there are various other kinds of projections, such as orthographic and point of view projections, that serve various functions in technical drawing. Orthographic estimates are a collection of multiple views that individually portray the item from various angles, usually in a two-dimensional layout. This method permits each aspect of the drawing to be lessened or taken full advantage of as needed, making sure quality in specifications and minimizing the threat of misinterpretation. Point of view illustrations, conversely, goal to develop an illusion of depth and measurement, resembling how the human eye views the globe. These drawings can be much less precise than orthographic projections due to their dependence on disappearing points and audience viewpoint, they can capture the aesthetic high qualities of a layout, making them valuable in marketing or conceptual presentations.

To effectively produce a technical drawing, it is vital to comprehend the conventions and signs that represent different features and dimensions. Inaccurate dimensions can lead to costly mistakes throughout manufacturing, making this aspect of technical drawing crucial for reliability and success.

Moreover, several software devices and applications promote the technical drawing procedure, improving the standard hand-drawing methods. Programs like AutoCAD, SolidWorks, and other Computer-Aided Design (CAD) software permit customers to produce complex 2D and 3D designs with far greater accuracy and adaptability than hands-on methods. These tools enable very easy adjustments, permitting rapid prototyping and iteration without the demand to recreate illustrations from the ground up. This digital transformation has significantly increased the layout and manufacturing processes across countless markets, driving development and enhancing performance.

In the context of industries today, recognizing exactly how to apply various views in technical drawing is not only essential for designers and designers yet likewise for manufacturers, item designers, and also marketing experts. The capability to communicate intricate concepts simply and plainly with these graphical depictions helps to straighten groups, from concept via to production. In collaborative settings, particularly in areas like building and manufacturing, clear technical illustrations guarantee that all stakeholders-- from developers to customers-- are on the very same page. This cooperation is vital for mitigating errors and lowering waste, ultimately preserving time and sources while cultivating creativity in the growth of originalities.

The capability to from thorough technical drawings, consisting of numerous views, is important for developing components that not only fit with each other appropriately but likewise run efficiently as component of more comprehensive systems. Additionally, as industries shift to electronic and automated processes, the abilities required to produce and translate technical illustrations will certainly be crucial to future skill pipes.

In conclusion, technical drawing encompasses various views, each of which plays a specific duty in sharing essential details regarding an item. As innovation and approaches for creating technical drawings proceed to breakthrough, understanding and applying these views successfully stays vital. As we move further into a period identified by fast technological evolution, the principles of technical drawing and its associated views will most certainly continue to be crucial in shaping the future of engineering, production, and layout.